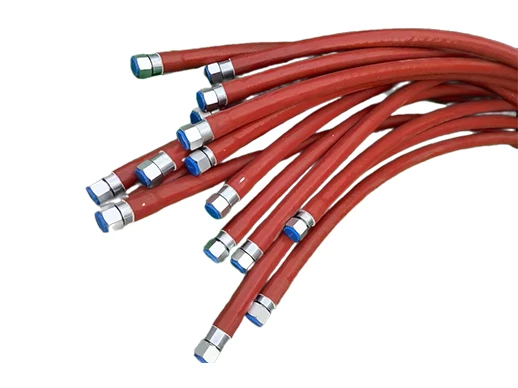

Metal hose with braided is a type of hose that possesses high strength and good flexibility, constructed from a metal tube and an outer layer of metal braid, featuring excellent pressure resistance, corrosion resistance, and sealing performance. The braided structure of the outer layer enhances the hose's wear resistance and shock absorption capability, allowing it to perform excellently in high-pressure and frequently vibrating environments. Braided metal hoses are suitable for the transmission of various media, including liquids, gases, and steam, and are widely used in fields such as petroleum, chemical engineering, machinery manufacturing, and construction, particularly in industrial systems that require high pressure and high strength.